E-BOOST innovation project

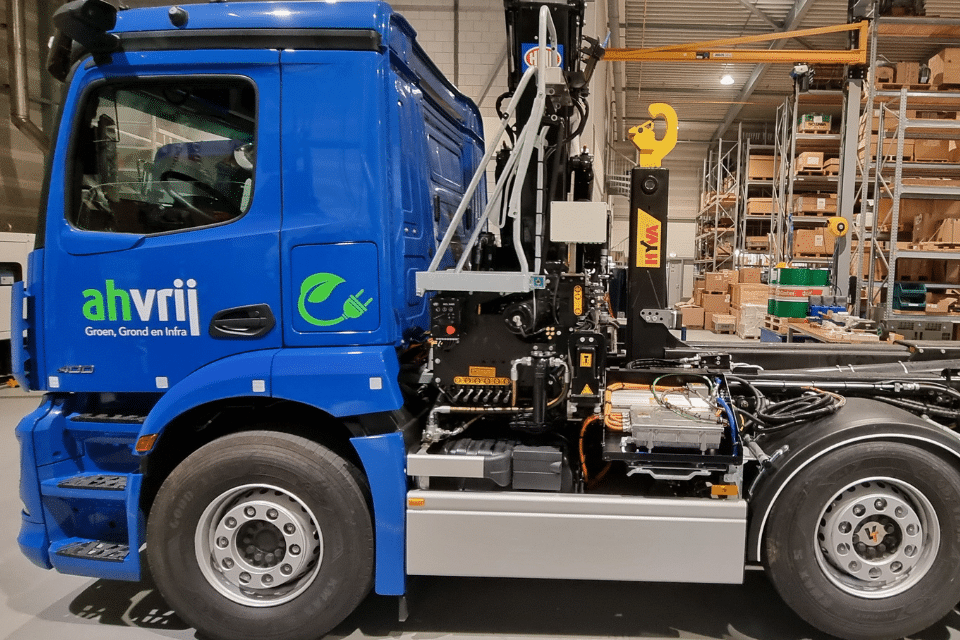

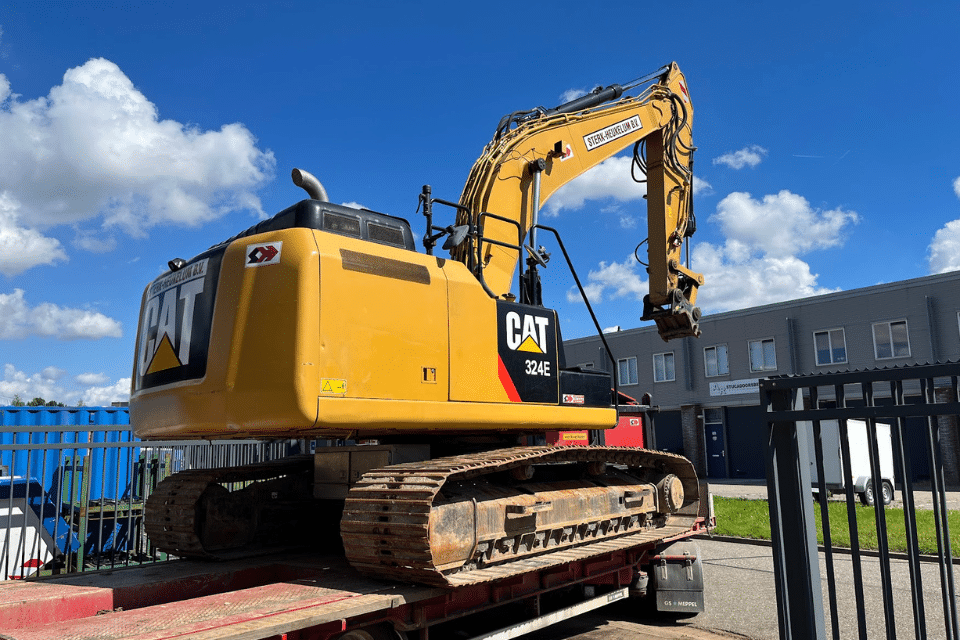

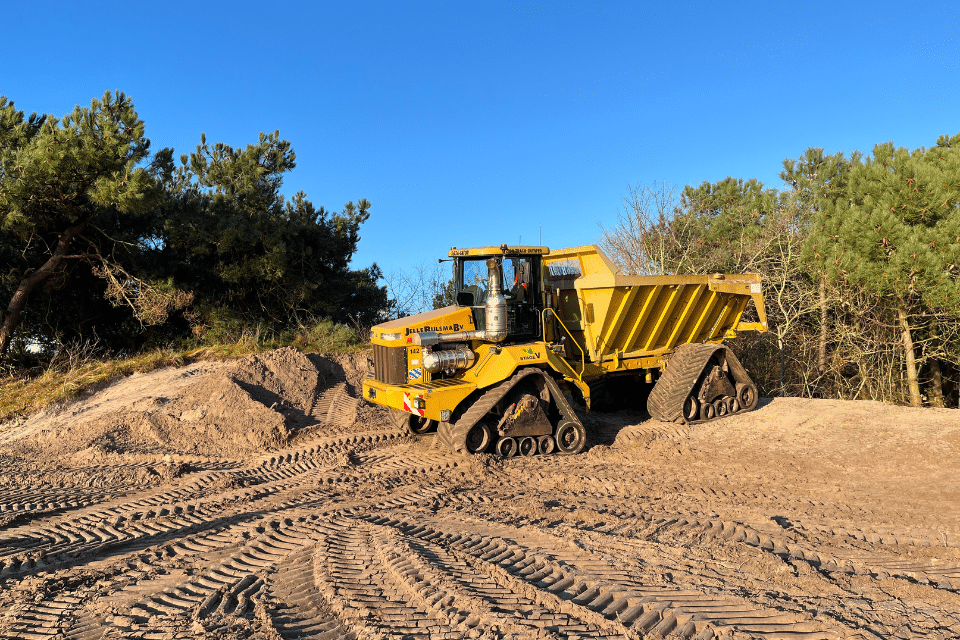

All major European truck manufacturers are currently introducing zero-emission, full electric commercial vehicle chassis with batteries, fuel cells or hydrogen ICE engines. Commercial vehicle chassis are built up to a complete vehicle by a Body Builder. Many truck bodies (e.g. Crane, Hook lift, Tipper, Compactor, etc.) require power to operate. Traditionally truck bodies are powered through the use of mechanical Power Take Off devices mounted to the diesel engine and/or the transmission. Electric vehicles typically do not offer this option and instead have a (single) High Voltage DC ePTO (electric Power Take Off) connection available.

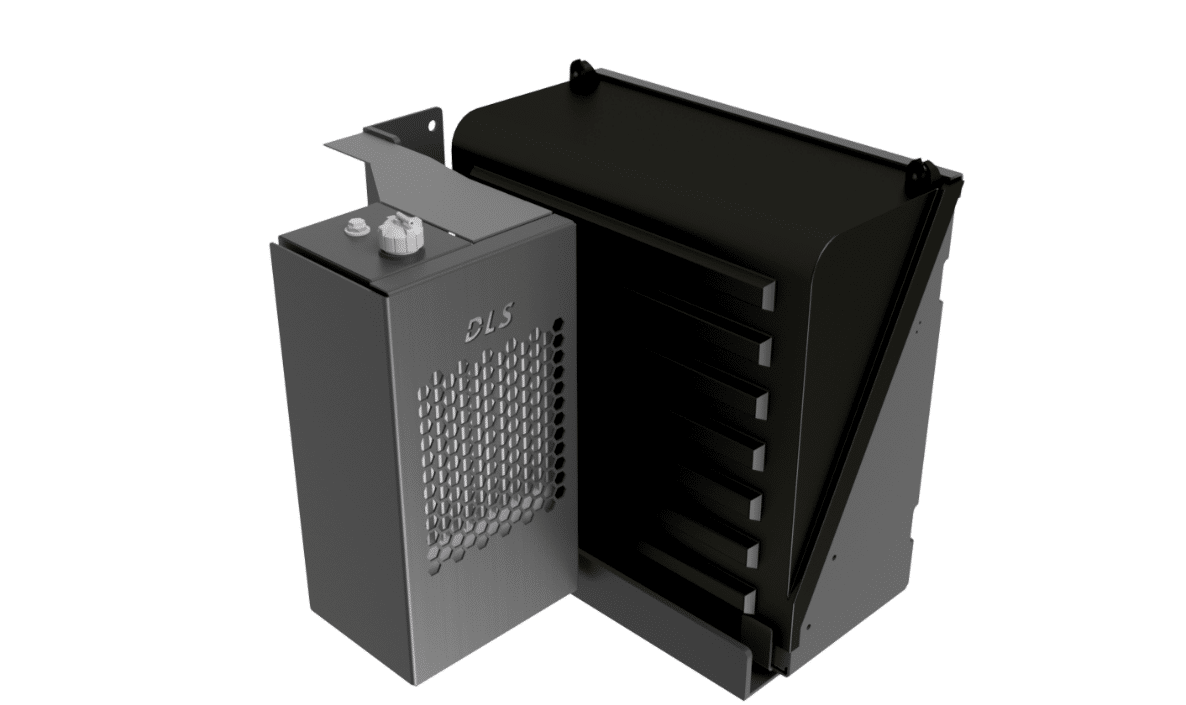

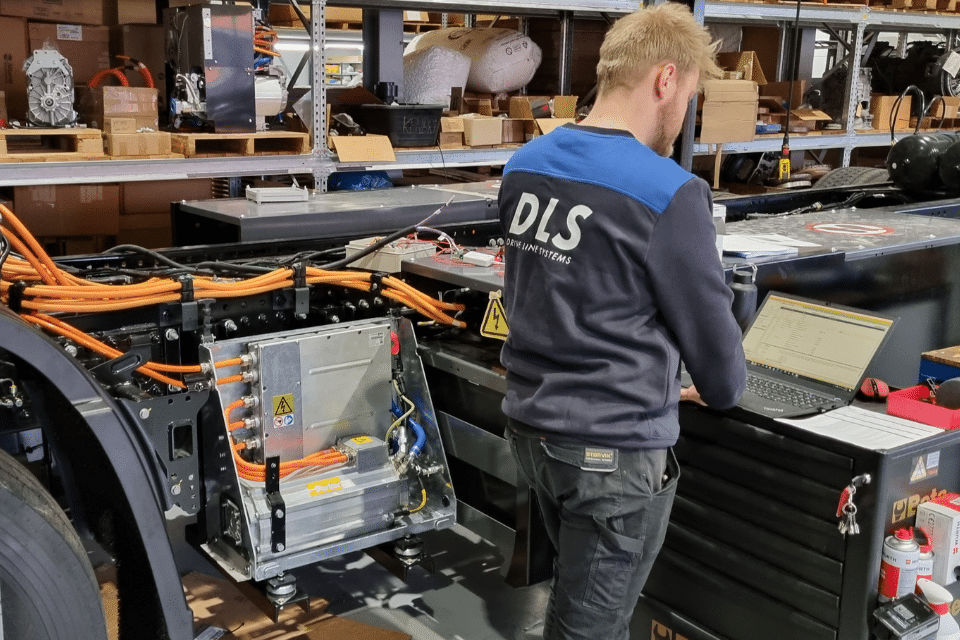

With support of the European Union, DLS is developing a modular system of ePTO components that transform the available HV DC power from the vehicle ePTO connection to a mix of mechanical, hydraulic and 230-400V AC power as needed to power a wide range of existing truck bodies and off-vehicle ancillaries. System components of this modular system include:

- Electric motors in various sizes up to ±90kW nominal power;

- High power galvanically isolated DC-AC inverters;

- Rotating generators up to ±100 kVA;

- Hydraulic pumps up to 350 bar;

- Choice of integrated or vehicle-connected cooling systems;

- Plug & play CAN-bus, HVIL and other low voltage electrical connections to the vehicle;

- Choice of digital or analogue in- and outputs for ePTO system control by the vehicle; body, programmable by the body builder via Bluetooth.

The first modules of the DLS modular ePTO system are already commercially available, with more being added throughout 2025. These modules assist and accelerate the build-up of full electric truck chassis into complete full electric vehicles and thereby improve the resilience of the EU electromobility sectors and reinforce the transformation into a greener economy.