Working more sustainable with the same machines

J. Veldhuizen B.V. takes steps to work more environmentally friendly

Working emission-free and sustainable is an important topic in the business operations of J. Veldhuizen B.V. A big part of the tools and machines Veldhuizen uses are already electric powered. For example, the company uses an electric rammer, band saw, and vibratory plate, but also works with an electric shovel and mobile excavator. Even the transport of equipment is fully electric.

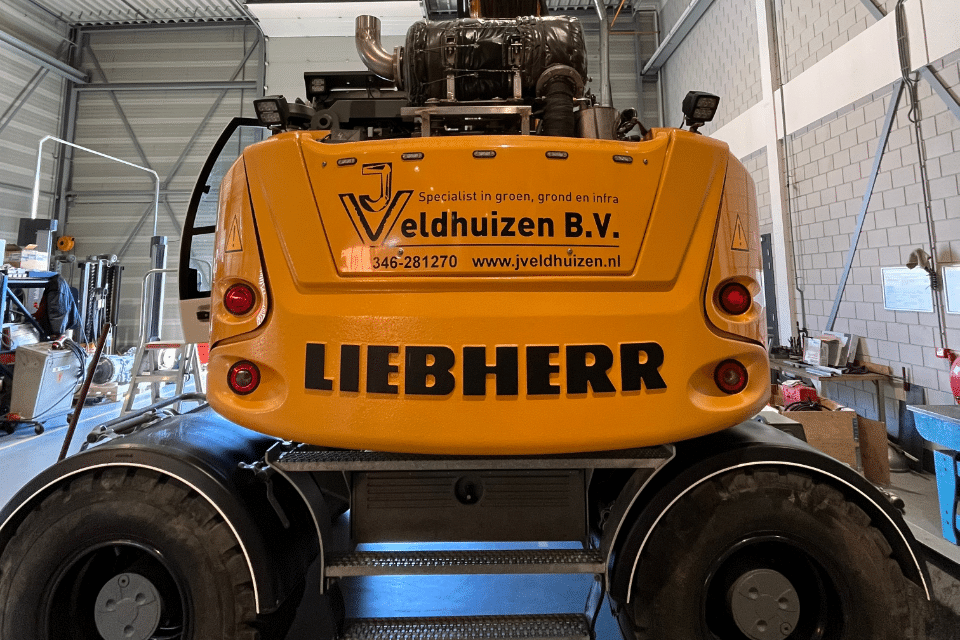

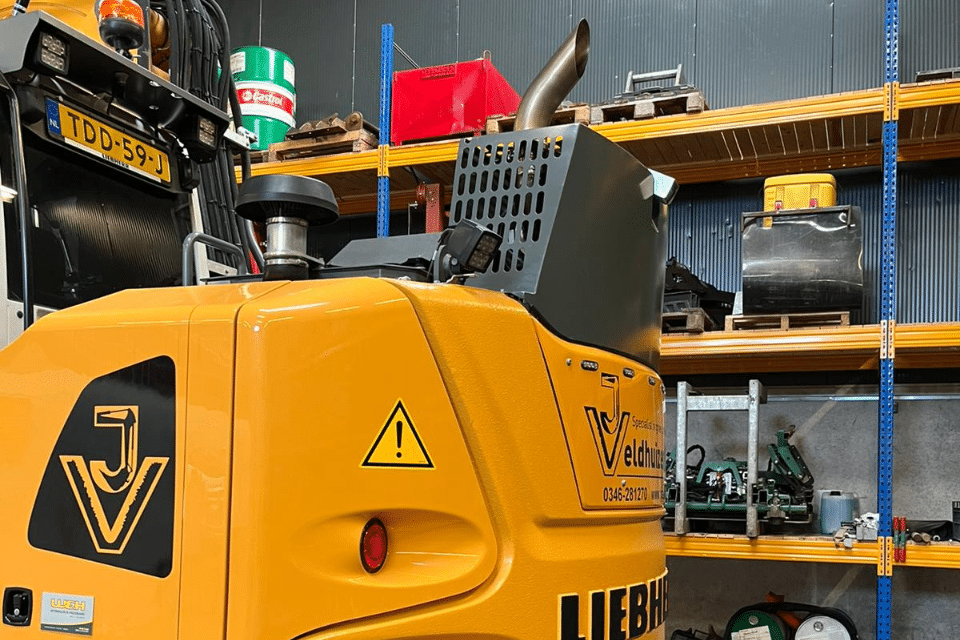

However, on some locations it is not possible to work with electric machinery and thus Veldhuizen has to use traditional diesel powered machines. One of these machines is their Liebherr 914 mobile excavator with Stage IV engine. To work in a more clean way the excavator could be replaced by a newer version with Stage V engine. However, the machine is only three years old, has not run for many hours, and is still in mint condition. Replacing the machine therefor would be a cleaner solution, but not a very sustainable one. When you include the current scarcity of resources, high material prices, and long lead times, replacing the excavator is no longer an option.

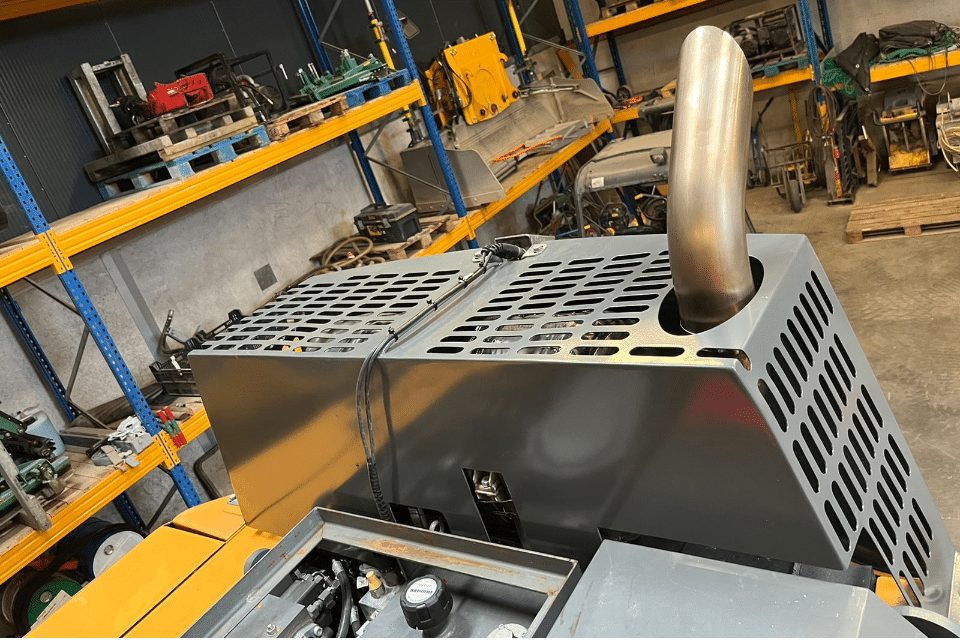

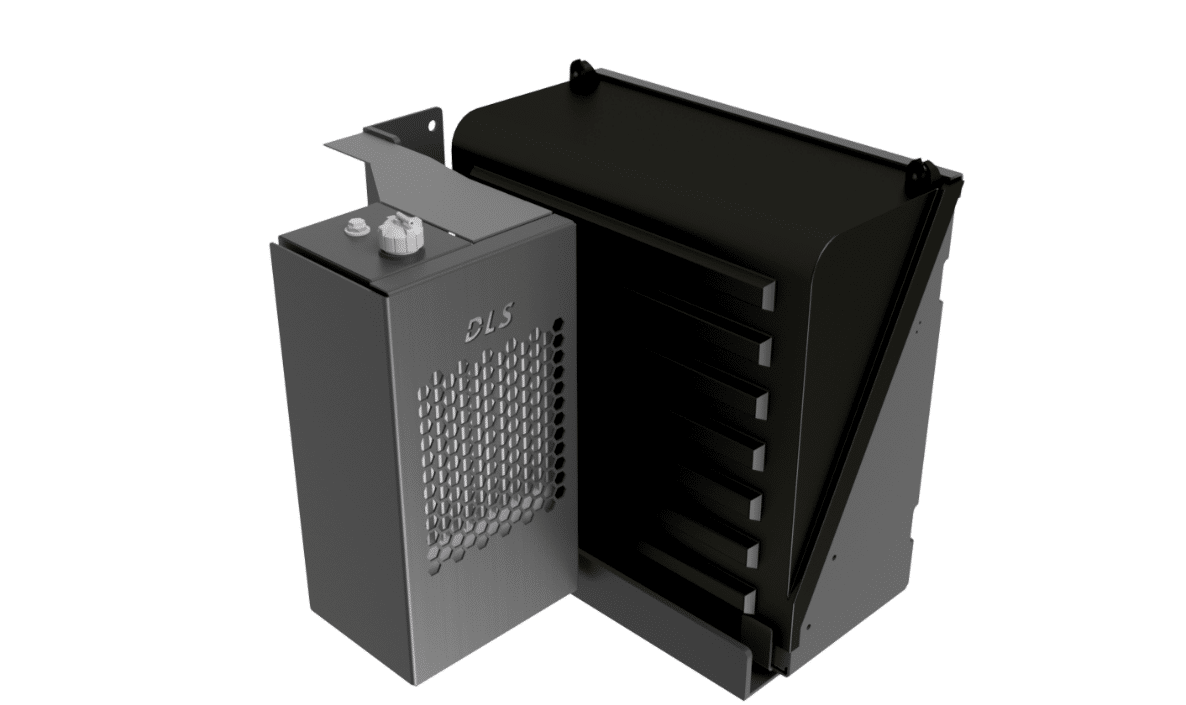

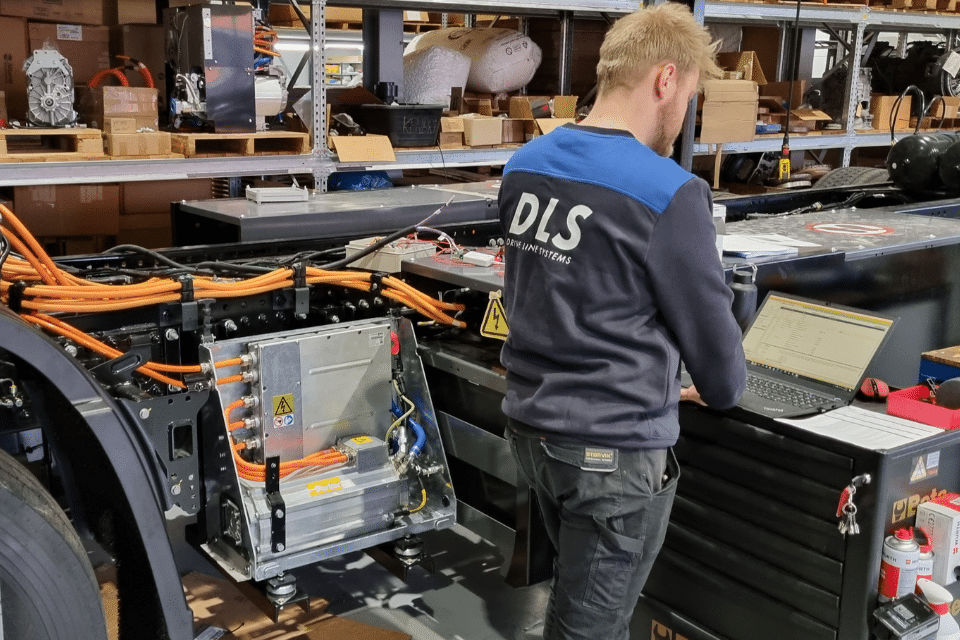

To still be able to work in a cleaner way Veldhuizen chose to make their current mobile excavator more sustainable. Stage IV engines are already equipped with an SCR system that reduces the engine’s nitrogen emissions (NOX). DLS now also equipped the machine with a retrofit DPF filter of HJS Emission Technology. This diesel particle filter, or soot filter, ensures a reduction of soot emissions of more than 99%. This makes that the emission values of the mobile excavator now comply with Stage V levels.

The soot filter Veldhuizen chose is equipped with an automatic regeneration function, which converts the collected soot in the filter into ashes. For this to work it is essential that the exhaust gasses have a high enough temperature. To guarantee this high temperature, the soot filter is insulated. The operator can see the status of the system on a display in the excavator’s cab.